Sarasota Florida Plant 33,000 sq.ft.

Sarasota Florida Plant 33,000 sq.ft.

Muncie Indiana Plant 30,000 sq.ft.

Muncie Indiana Plant 30,000 sq.ft.

About Us

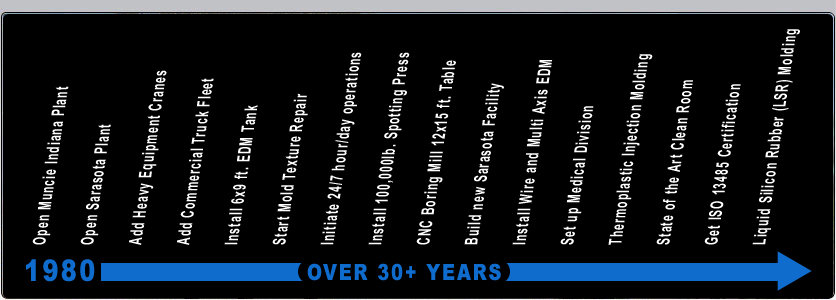

Established in 1980 we now have access to over 60,000 square feet of high tech manufacturing and injection molding, in two climate controlled plants. Throughout the years SPE has continuously invested into upgrading our engineering and tooling capabilities, which has resulted in our customers recognizing the extreme precision we apply to making new molds or fixing damaged molds, including the most complex texturing applications.

Our Indiana plant with equipment like multiple 10,20,or 30 ton cranes, largest 6'x9' EDM tank, a fleet of custom built Trucks, and the ability to lift and repair complex textured molds over 100,000lbs., is a virtual heavy mold emergency room, meeting the needs of major automotive clients in just a matter of hours.

Our Florida plant, with 30+ years of engineering experience and access to the latest CAD, CNC, and EDM technology, can design and develop the most precise and productive molds. In addition to building molds, we also have a large variety of Injection Mold machines ranging from 28-390 tons, capable of meeting the needs of small and large corporate customers.

Our Medical Division is built around a high tech Clean Room capable of full injection mold production, including LSR (Liquid Silicon Rubber) injection molding. With an ISO 13485 Certification, and operating under ISO 14644 Class 6,7, and 8 standards, we can meet the needs of customers looking for short or long production runs.

The Medical Division through our advanced in-house Engineering department, also offers a complete Product Prototype development process, for new innovative Medical Packaging, Devices, or Implants.

Using our proprietary APEM System, we have established a process which constantly evaluates the relationship and changes within raw material cost, production cycle, and mold design and engineering, resulting in designs that achieve maximum profit margins for our customers.

Our Indiana plant with equipment like multiple 10,20,or 30 ton cranes, largest 6'x9' EDM tank, a fleet of custom built Trucks, and the ability to lift and repair complex textured molds over 100,000lbs., is a virtual heavy mold emergency room, meeting the needs of major automotive clients in just a matter of hours.

Our Florida plant, with 30+ years of engineering experience and access to the latest CAD, CNC, and EDM technology, can design and develop the most precise and productive molds. In addition to building molds, we also have a large variety of Injection Mold machines ranging from 28-390 tons, capable of meeting the needs of small and large corporate customers.

Our Medical Division is built around a high tech Clean Room capable of full injection mold production, including LSR (Liquid Silicon Rubber) injection molding. With an ISO 13485 Certification, and operating under ISO 14644 Class 6,7, and 8 standards, we can meet the needs of customers looking for short or long production runs.

The Medical Division through our advanced in-house Engineering department, also offers a complete Product Prototype development process, for new innovative Medical Packaging, Devices, or Implants.

Using our proprietary APEM System, we have established a process which constantly evaluates the relationship and changes within raw material cost, production cycle, and mold design and engineering, resulting in designs that achieve maximum profit margins for our customers.