Available Services

APEM System

Advanced Precision Engineered Molds

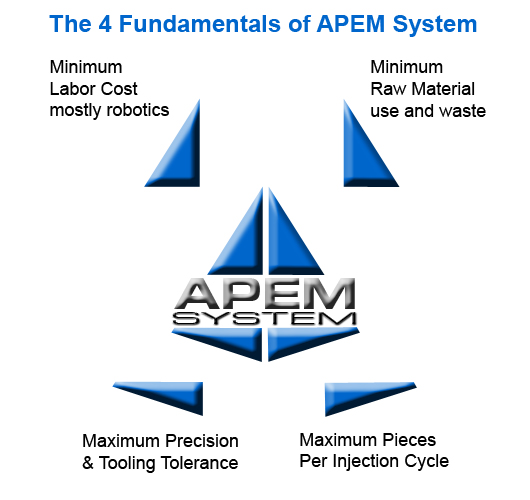

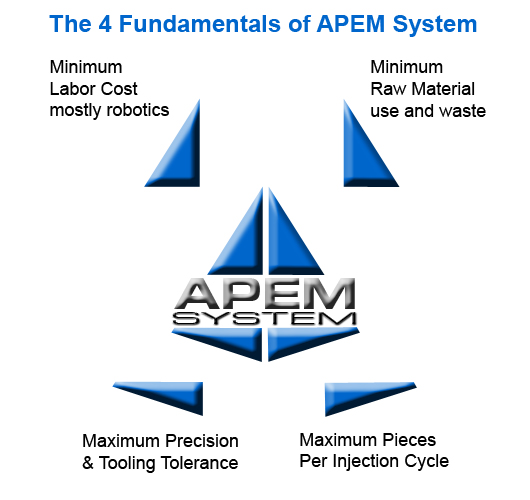

The APEM System is an exclusive process developed by SPE primarily for but not restricted to its Medical division. The APEM system is an interactive Mold development process between design, engineering, and tooling, based upon four fundamental principles, which must all be part of any Mold development.

With the APEM System each of these four fundamentals are integrated into each mold development process through a carefully constructed formula, resulting in maximum productivity and profit margins for all our clients.

With the APEM System each of these four fundamentals are integrated into each mold development process through a carefully constructed formula, resulting in maximum productivity and profit margins for all our clients.

- Raw Material use and waste… Controlling raw material usage and cost, is not only important, but becomes an absolute critical component of any and all injection mold design or use.

- Labor use and cost… To achieve maximum profit margins, production run labor cost must be reduced or eliminated, and robotics applied as often as possible.

- Production Volume… Each and every injection cycle must produce the maximum number of pieces, reducing run time, labor cost, and material use.

- Precision Tooling… Design and Tooling must achieve the highest possible precision and meet exceptional tolerances, which contribute to or eliminate post production process, and result in greater quality.